- Out-of-Stock

The XHORSE 3D Xscanner 3D is a high-precision optical scanner designed for fast and detailed 3D capture of physical objects. Featuring an advanced blue laser light source and a system of 7 laser pairs + 1 single beam, it performs up to 420,000 measurements per second with an accuracy of up to 0.05 mm.

Compact, ergonomic, and highly portable, it is ideal for design studios, technical laboratories, manufacturing workshops, and industrial applications requiring fine precision.

Laser Category: Class I (eye-safe)

Measurement Rate: 420,000 points/s

Scanning Accuracy: up to 0.05 mm*

Scanning Resolution: up to 0.05 mm

Image Resolution: 1920 × 1200

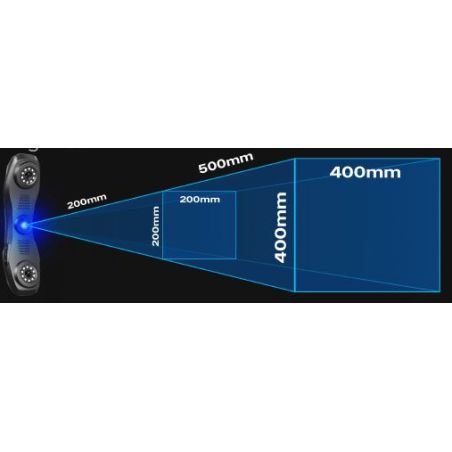

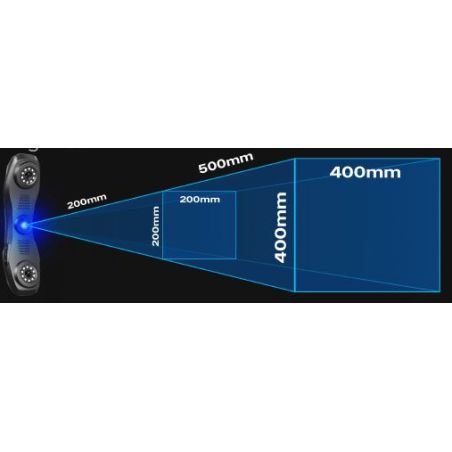

Datum Distance: 350 mm

Scanning Area (per frame): up to 400 × 400 mm

Weight: 425 g

Dimensions: 239 × 66 × 62 mm

Output Formats: XPRO, PLY, TXT, STL, OFF, OBJ

Data Transfer: USB 3.0

Operating Temperature: -20°C to 40°C

Operating Humidity: 10%–90% (non-condensing)

*Maximum accuracy guaranteed for distances under 200 mm.

The Xscanner 3D uses high-stability blue laser technology, offering excellent resistance to ambient light interference. Its 20 built-in LED lights eliminate shadows for clearer, more detailed scans.

An intelligent marker-matching algorithm ensures outstanding image stabilization and frame-to-frame alignment, even during fast scanning.

Calibration is quick and intuitive, completed in just 1–2 minutes using a high-precision lithographically produced calibration board, ensuring repeatable accuracy.

The Xscanner 3D software features a powerful and intuitive interface:

Real-time scanning preview

Point cloud editing and mesh generation

Merging, cleanup, and export tools

Broad compatibility with most CAD, CAM, and modeling software (STL, OBJ, PLY, etc.)

The system seamlessly integrates with five-axis machining centers using the EtherCAT industrial protocol, allowing the workflow to go from scan to machining:

Capture the object and generate a 3D model.

Import the model into 5-axis programming software.

Generate G-code via post-processing.

Import the G-code into the machining center for production.

The Xscanner 3D supports a wide range of materials:

Metals: aluminum, copper alloys

Plastics: PVC, MDF, acrylic, resin, PP, PC, PS

Others: wood, stone, wax

Wireless probe

Calibration block

Digital Twin simulation software

Shockproof carrying case

Mounting accessories (tripod, robotic arm, quick-release base)

Recommended environment: stable surface, controlled temperature, low vibration.

The XHORSE 3D Xscanner 3D is suitable for a wide range of industries:

Automotive: reverse engineering, design, inspection, and modification

Industrial manufacturing: quality control, prototyping, model reproduction

Medical field: orthotics, prosthetics, anatomical modeling

Education and research: design, engineering, and digital modeling training

Cultural heritage and art: conservation and digital archiving

Creative design: jewelry, sculpture, and 3D modeling

| Aspect | Xscanner 3D | 3D Printer |

|---|---|---|

| Principle | Non-contact optical scanning | Additive layer-by-layer fabrication |

| Materials | Metals, plastics, composites | Polymers, resins, powders |

| Precision | Very high (up to 0.05 mm) | Moderate, depends on technology |

| Purpose | 3D capture and reproduction | 3D creation and manufacturing |

For beginners, the system includes:

Step-by-step interactive tutorials

Preloaded sample models

Quick installation and calibration guide

Full Windows workstation compatibility

The XHORSE 3D Xscanner 3D delivers speed, precision, and mobility in one compact design. It transforms real-world geometry into accurate digital data for design, engineering, and production workflows.

With its advanced optics, intuitive software, and wide compatibility, it stands as a benchmark for high-precision 3D scanning across industries.

1. What scanning technology does the Xscanner 3D use?

The Xscanner 3D uses a blue laser line projection system with 7 pairs of laser crosses plus 1 single laser line for deep hole scanning. This ensures high-speed, high-accuracy 3D data capture.

2. What is the measurement rate of the Xscanner 3D?

The scanner performs up to 420,000 measurements per second, providing ultra-fast data acquisition for complex geometries.

3. What is the maximum scanning accuracy?

The Xscanner 3D achieves up to 0.05 mm accuracy when the scanning distance does not exceed 200 mm.

4. What is the maximum single-frame scanning area?

Each frame can capture an area of up to 400 mm × 400 mm, with a reference distance of 350 mm.

5. What file formats does the Xscanner 3D support?

The scanner supports multiple output formats including XPRO, PLY, TXT, STL, OFF, and OBJ, compatible with most 3D modeling and CAD software.

6. Which communication protocol does the Xscanner 3D use?

It uses the EtherCAT industrial protocol, allowing smooth integration with five-axis CNC machining centers and other smart manufacturing systems.

7. What materials can the Xscanner 3D scan?

It supports a wide range of materials, including:

Metals: aluminum, copper alloys

Plastics: PVC, MDF, acrylic, resin, PP, PC, PS

Others: wood, stone, wax

8. Is the Xscanner 3D software included and licensed?

Yes. The Xscanner 3D comes with dedicated software for scanning, point cloud editing, mesh processing, and model export. The license is included with the purchase, and software updates are provided free of charge.

9. How difficult is the calibration process?

Calibration is quick and user-friendly. It only takes 1–2 minutes to complete using the high-precision calibration board included with the scanner.

10. How does the Xscanner 3D work with a five-axis machining center?

The workflow is as follows:

Scan the physical part and generate a 3D model.

Import the model into the five-axis programming software.

Use post-processing software to create the G-code.

Load the G-code into the machining center for precise production.

11. What is the difference between a 3D scanner and a 3D printer?

A 3D scanner captures the geometry of an existing object, creating a digital model.

A 3D printer builds a physical object layer by layer from digital data.

The scanner focuses on measurement and reproduction, while the printer focuses on manufacturing.

12. What accessories come with the Xscanner 3D?

Included and optional accessories include:

Wireless probe

Calibration block

Digital Twin simulation software

Shockproof carrying case

Tripod or robotic arm mounts

13. What is the ideal working environment?

It’s recommended to place the scanner on a stable, flat surface in a controlled temperature environment with low vibration and humidity for optimal precision.

14. Can I use the scanner immediately after delivery?

Yes. The Xscanner 3D is ready to use out of the box after installation of the software and a short calibration process.

15. In which industries can the Xscanner 3D be applied?

It is suitable for multiple industries, including:

Automotive modification and reverse engineering

Industrial design and quality control

Medical modeling and orthopedics

Education and research

Cultural heritage preservation

Art, jewelry, and creative design

16. What after-sales service and warranty are provided?

The Xscanner 3D includes technical support, user manuals, and official documentation. Warranty coverage applies from the date of purchase according to regional policies.

KEYFIRST is the official distributor of the XHORSE 3D Xscanner 3D in France and Europe.

Our Keyfirst+ service allows you to access additional content such as demonstration videos and technical information

Would you like to get more information about this product?

Keyfirst+Technical support for your vehicle key programming

With Keyfirst+, you’ll receive tailored technical assistance for your needs! In addition to a 5% discount on all your online orders, this service provides you with access to personalized support. Our experts are available 6 days a week to assist you remotely with your procedures, ensuring you receive constant and effective support. Don’t work alone—join the Keyfirst community!