- Out-of-Stock

The XHORSE XMACHINE 3D represents over a decade of R&D in high-precision multi-axis machining.

Built to combine mechanical rigidity, dynamic motion and micrometric accuracy, it’s designed for engineers, educators, designers, and small-scale manufacturers who require industrial-grade performance in a desktop footprint.

Its horizontal 5-axis simultaneous architecture provides full-motion freedom for machining complex parts from every angle — no manual repositioning, no loss of precision.

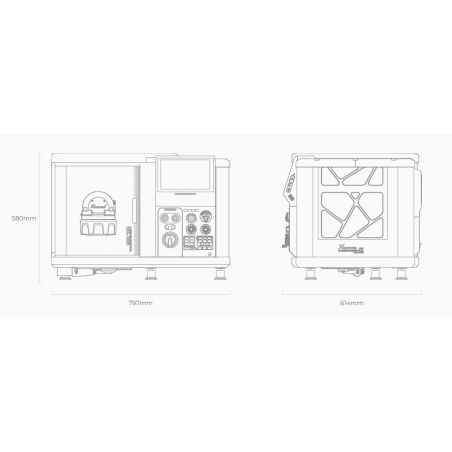

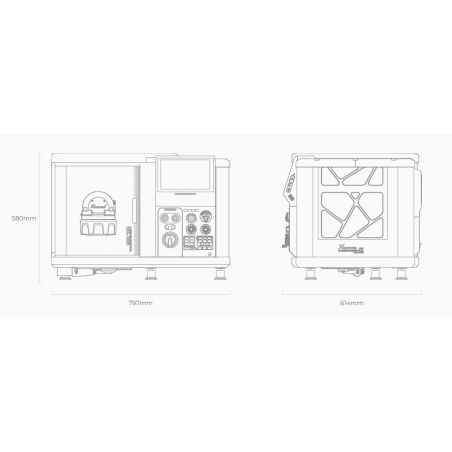

Compact yet robust (797 × 614 × 580 mm, ≈ 130 kg), the XMACHINE brings production-class capability to your workspace.

Horizontal gantry construction in high-density cast steel for maximum rigidity and vibration damping.

X/Y/Z linear axes use precision-ground ball screws, driven by self-developed XHORSE servo motors with absolute encoders.

Travel ranges: X = 156 mm | Y = 203 mm | Z = 125 mm.

Rotary axes A and C:

A-axis = –30° to +110° with harmonic reducer for angular stability.

C-axis = continuous 360° rotation via direct-drive motor.

Rotary table Ø100 mm, max load 10 kg, concentricity ≤ 0.005 mm.

This kinematic design enables continuous multi-surface machining in a single setup, reducing clamping errors and boosting productivity.

Spindle speed: up to 18 000 rpm, Permanent-Magnet Synchronous Motor (PMSM).

Active air-cooling system with side duct and custom wind shield for thermal stability.

Rated power 2.2 kW delivers constant torque for aluminum, brass, engineering plastics, and hardwoods.

Rapid traverse (X/Y/Z): ≥ 4000 mm/min for smooth, precise motion in complex toolpaths.

EtherCAT protocol ensures real-time synchronization and sub-millisecond axis communication.

Automatic centering and workpiece measurement using optical sensors and wireless probing.

Closed-loop axis calibration – dynamic error correction in under 5 minutes.

Concealed automatic tool changer:

6-position magazine integrated within the chassis,

automatic unfolding/retraction during operation,

reduces setup time and improves workflow efficiency.

Automatic tool-length measurement and wear compensation extend tool life and ensure consistent results.

Together, these systems deliver a fully automated CNC experience that combines precision with productivity.

Each unit includes the proprietary XMachine-NCS numerical control system, engineered by XHORSE for unmatched integration.

Core features:

Intuitive graphical interface with real-time 3D simulation.

RTCP (Rotating Tool Center Point) and 3 + 2 positioning support.

Flexible multi-axis interpolation and advanced motion planning.

Thermal and kinematic error compensation for long-term accuracy.

Real-time visualization of toolpaths, feed rates, and cutting loads.

Fully compatible with major CAM software (Fusion 360, MasterCAM, SolidCAM, Powermill, etc.).

A dedicated XHORSE-CAM suite is under development for complete workflow integration.

Supported materials: aluminum, copper, brass, POM, ABS, PA, PMMA, wood, machinable wax, resins and composites.

Typical applications:

Precision mechanical parts and molds.

Prototyping for engineering and industrial design.

Artistic and decorative projects with high-detail engraving.

Education and training in CNC manufacturing and automation.

Custom tool production and competition prototyping (robotics, automotive, aerospace).

Air-cooling system – no cutting fluid required, minimal maintenance.

Simple assembly – delivered pre-aligned and ready for quick setup.

Transparent protective enclosure for safe operation and continuous visual control.

Low noise and vibration levels, suitable for offices, labs or training centers.

For over ten years, KEYFIRST has been the official XHORSE distributor in Europe, working daily with Shenzhen’s engineering team to deliver:

Factory-certified technical support,

Professional training and installation guidance,

Fast delivery and localized after-sales service,

Pre-delivery inspection and calibration on every machine.

This partnership ensures that each XMACHINE is delivered fully tested, calibrated, and supported by an experienced European team.

| Parameter | Specification |

|---|---|

| Structure | Horizontal gantry, rigid steel frame |

| Axes | 5 (X/Y/Z/A/C simultaneous) |

| Travel (X/Y/Z) | 156 / 203 / 125 mm |

| A-Axis Range | –30° ~ +110° |

| C-Axis Range | 360° continuous |

| Rapid Feed | ≥ 4000 mm/min |

| Spindle Speed | 18 000 rpm |

| Power | 2.2 kW |

| Tool Changer | 6 automatic positions |

| Cooling System | Air cooling |

| Machine Weight | ≈ 130 kg |

| Dimensions | 797 × 614 × 580 mm |

| Max Workpiece | 100 × 100 × 100 mm / ≤ 10 kg |

The XHORSE XMACHINE 3D embodies the vision of Industry 4.0 – a compact, automated 5-axis machining center that brings industrial power to the desktop.

Thanks to KEYFIRST, official European distributor for over a decade, you benefit from direct manufacturer expertise, training, service, and complete technical support.

XMACHINE 3D – where innovation, engineering and precision converge to reshape modern manufacturing.

Our Keyfirst+ service allows you to access additional content such as demonstration videos and technical information

Would you like to get more information about this product?

Keyfirst+Technical support for your vehicle key programming

With Keyfirst+, you’ll receive tailored technical assistance for your needs! In addition to a 5% discount on all your online orders, this service provides you with access to personalized support. Our experts are available 6 days a week to assist you remotely with your procedures, ensuring you receive constant and effective support. Don’t work alone—join the Keyfirst community!